fittings are used for the reliable securing of containers Which can be classified in 2 parts.

- Fixed fitting

- loose fitting

- Fixed fittings – Stacking cones, foundations, deck foundations, lashing plates, eyes, pots, d-rings. Fixed fittings are integrated into the hull structure or hatch covers.

- Loose fittings – Twistlocks, Base locks, spanners, lashing rods, and turnbuckles.

In this article, we will read about the following –

- Base locks

- Mid locks

- Twist locks

- Lashing rod

- Turn Buckle

- Stowage bins and lashing equipment stowage design

1. BASE LOCKS

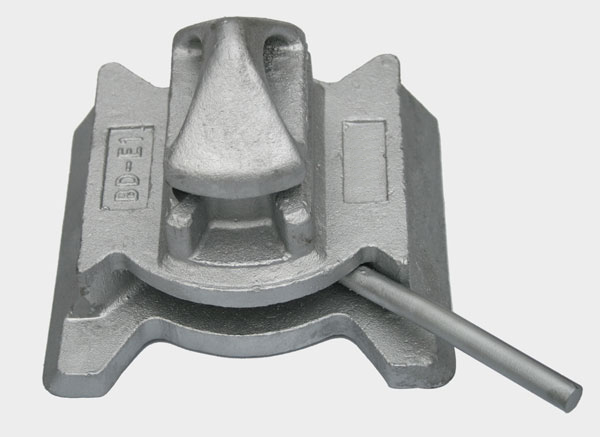

It is the foundation of container securing. The bottom-most layer of containers or say the base tier of the container is secured by base locks. Base lock sits in iso socket and once the container is placed on it the handle in front is turned to left side. In the above image the handle is right side which indicates it is in open position. Once the container is loaded we turn the handle to left.

2. MID LOCKS

They are only used in the case of 20 feet containers, Mid locks are not required when loading a 40 feet container. As the name suggests it is in the middle of the hatch cover.

The image below shows the mid lock.

3. TWIST LOCKS

Each tier of the container is locked with the other tier of the container with twist locks. If not loaded properly or if the container does not sit properly its because of a twist lock. So while loading the crew keeps a close watch and report if any twist lock problem is noted. The image below shows the use of twist lock.

4&5 – LASHING BRIDGE, LASHING ROD & TURN BUCKLE

Lashing rod design

- The design of containership securing systems and weight should take into account the practical abilities of the workers to lift, reach, hold, control, and connect the components in all situations anticipated in the cargo securing plan.

- The maximum length of a lashing rod should be sufficient to reach the bottom corner fitting of a container on top of two high cube containers

- The head of the lashing rod that is inserted in the corner fitting should be designed with a pivot/hinge or other appropriate devices so that the rod does not come out of the corner fitting accidentally.

- The rod’s length in conjunction with the length and design of the turnbuckle should be such that the need of extensions is eliminated when lashing high cube (9’6″) containers.

- Lightweight rods should be provided where special tools are needed to lash high cube containers.

Turnbuckle design

- Turnbuckle end fittings should be designed to harmonize with the design of lashing rods.

- Turnbuckles should be designed to minimize the work in operating them.

- Anchor points for turnbuckles should be positioned to provide safe handling and to prevent the bending of rods.

- To prevent hand injury during tightening or loosening motions, there should be a minimum distance of 70 mm between turnbuckles.

- The turnbuckle should incorporate a locking mechanism which will ensure that the lashing does not work loose during the voyage.

- The weight of turnbuckles should be minimized as low as possible consistent with the necessary mechanical strength.

6. Storage bins and lashing equipment stowage design

- Bins or stowage places for lashing materials should be provided.

- All lashing gear should be stowed as close to its intended place of use as possible.

- The stowage of securing devices should be arranged so they can easily be retrieved from their stowage location.

- Bins for faulty or damaged gear should also be provided and appropriately marked.

- Bins should be of sufficient strength.

- Bins and their carriers should be designed to be lifted off the vessel and restowed.